Automotive

GRM Consulting has a long and rich history in the Automotive Industry. We have covered almost every analysis type possible throughout the vehicle structure. We have delivered interior systems, exterior systems, suspension and powertrain systems from simple stress analysis right up to advanced methods development. Typically we use optimisation methods to derive cutting edge designs to drive structures into new areas. We have worked for almost every automotive manufacturer and parts supplier worldwide. We have backed up this work by developing material models of plastics, composite and steels at high strain rates to capture performance in multiple scenarios.

We are at the forefront of lightweighting using optimisation techniques to thoroughly understand designs and their performance across many load-cases. We use these methods to brainstorm solutions for new materials and manufacturing techniques. It is fair to say that GRM’s technology, techniques and expertise are behind many of automotive products on today’s roads.

Currently, we’re engaged by OEMs and Tier suppliers to deliver lightweight designs as it becomes a greater focus due to the industry’s need to reduce CO2 emissions.

Body Systems

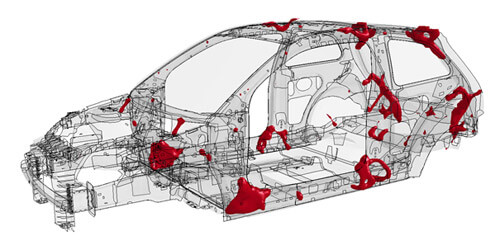

Our work in the development of body-in-white (BIW) structures is extensive and covers all the typical load-case requirements such as crash, modal, global and local stiffness and NVH. We work closely with design engineers to ensure manufacturability and have a great appreciation of the constraints of panel assembly order and production line limitations. Our optimisation methods are particularly advanced in this area and you can see how the RDM® technique supports the delivery of lightweight structures here.

Our work in the development of body-in-white (BIW) structures is extensive and covers all the typical load-case requirements such as crash, modal, global and local stiffness and NVH. We work closely with design engineers to ensure manufacturability and have a great appreciation of the constraints of panel assembly order and production line limitations. Our optimisation methods are particularly advanced in this area and you can see how the RDM® technique supports the delivery of lightweight structures here.

One of our unique skills is the development of composite components and our software and stress analysis techniques have been used to deliver a recent composite body project with Jaguar Land Rover, an overview of which can be seen in the Advanced Engineering Presentation. The aim was to improve CO2 emissions from the vehicle through lightweighting, and this is a task which many manufacturers across the industry are facing. Having the ability to test products in the way that we do gives a significant time and cost saving advantage while allowing tests in multiple scenarios in a short amount of time.

Powertrain Systems

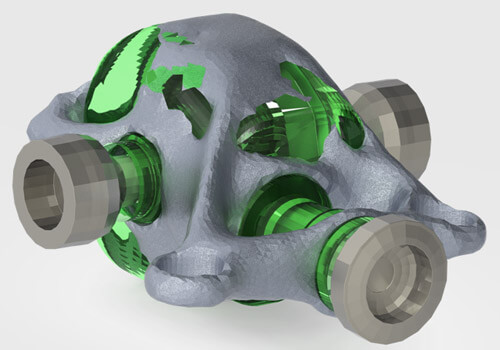

The analysis and optimisation of lightweight powertrain systems is an exciting new area of exploration for GRM. Our collaboration with JLR and Ricardo in a recent project has delivered a significant weight saving, as summary of which can be found at this link. We’ve tailored our optimisation methods to the unique challenges of the powertrain and shown clearly how different materials are required in different applications.

The analysis and optimisation of lightweight powertrain systems is an exciting new area of exploration for GRM. Our collaboration with JLR and Ricardo in a recent project has delivered a significant weight saving, as summary of which can be found at this link. We’ve tailored our optimisation methods to the unique challenges of the powertrain and shown clearly how different materials are required in different applications.

Interior Systems

GRM's team has developed a number of novel interior solutions to meet legislation within the bounds of low and high-volume manufacturing processes. This has covered airbags, restraints and many different types of seating. Numerous correlation studies have also been carried out on full vehicles, as well as rig based work. This is backed up by an intimate knowledge of the construction of the numerous impactor types and how small details present in these devices can influence test results.

Exterior Systems

GRM has developed bumpers, lights, bonnets and all associated components to meet user requirements as well as being experts in pedestrian protection. Our extensive experience in the engineering analysis of Pedestrian Protection systems has been developed working on many vehicle development programmes. This work has been carried out for the majority of the European OEMs and many others around the world during the past decade.

GRM's engineers have developed Pedestrian Protection solutions for all areas of the vehicle front end. These have included friable headlights for the Lower and Upper Legs and compliant hinges and bonnet latches for Head impacts. Recent work has covered windscreen crack propagation studies and simulation for detailed EuroNCAP scoring with the Head. GRM is currently developing optimisation techniques to deliver consistent intrusion and HIC results across a bonnet. The company is also experienced with the wide variety of materials present in a vehicle front end.

Suspension Systems

Our suspension system work has included all traditional materials for durability and modal performance, balancing these with stiffness requirements through the use of optimisation techniques. We have also explored composite suspension systems and met the challenges associated with developing for high-volume applicable material types.