ElectrificationCase Studies

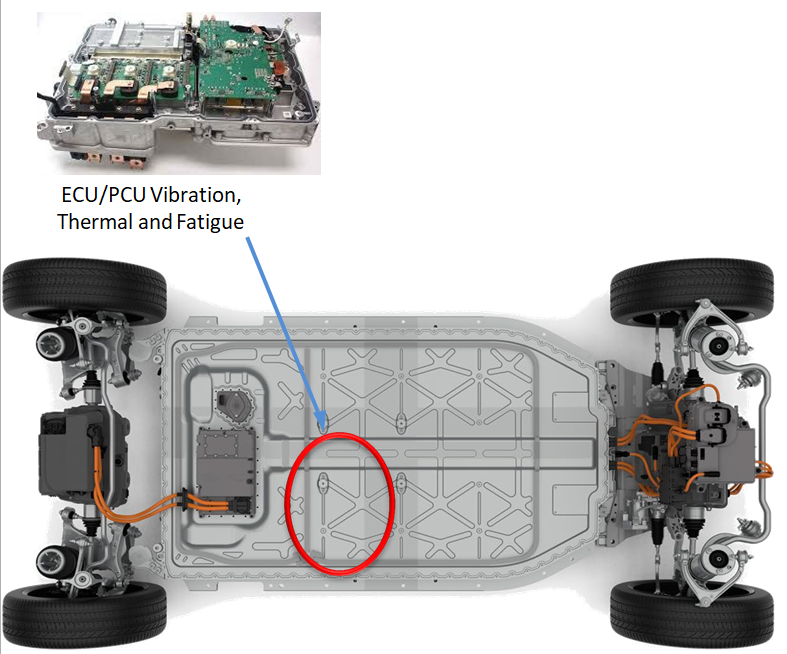

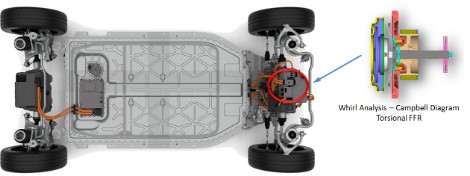

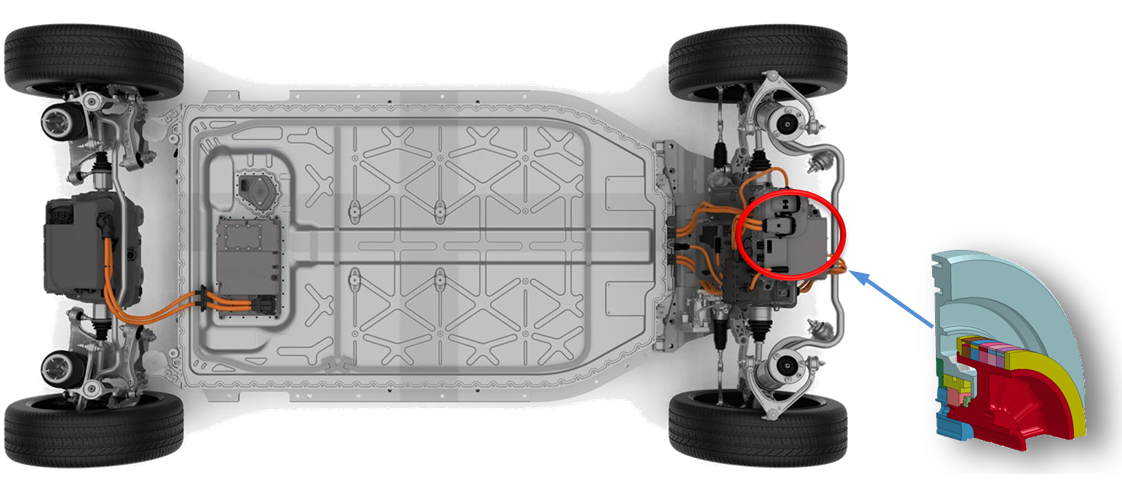

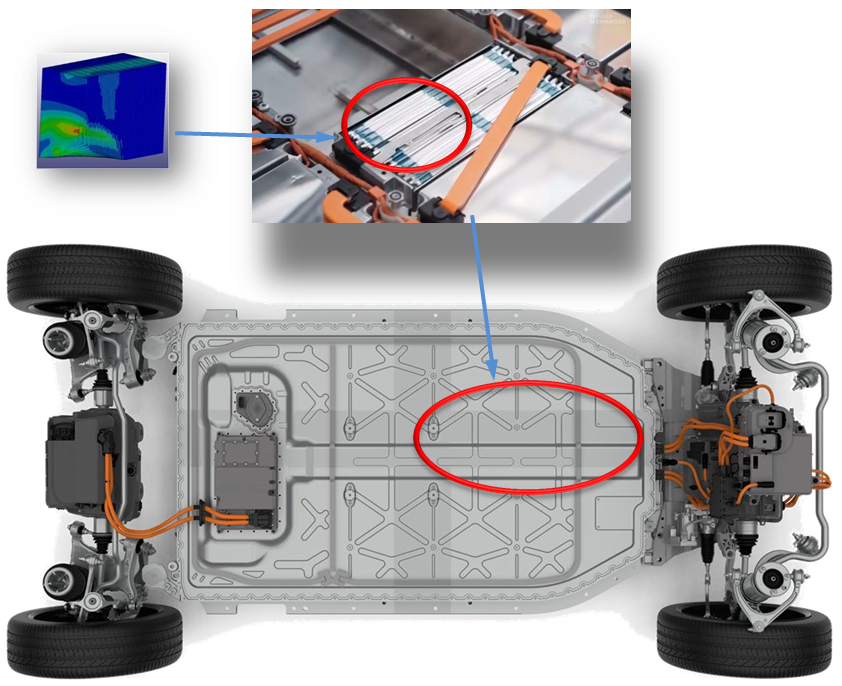

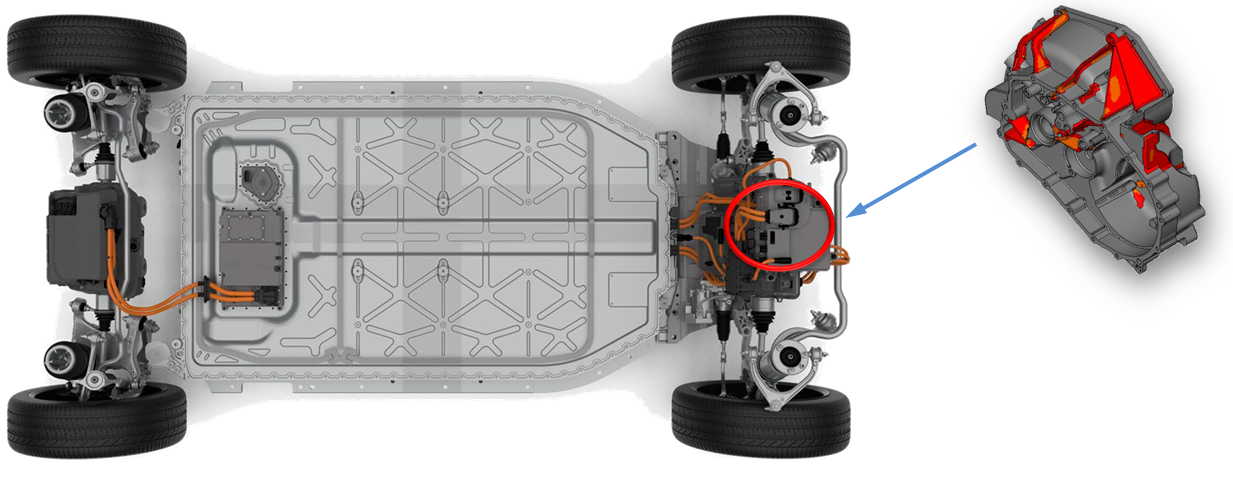

It is an exciting time in the automotive industry as there has been a revolution in the field of electrification. GRM have provided both component and systemic level solutions for the optimisation of a variety of projects.

With market forces accelerating the drive to EVs, the engagement of innovative and cutting edge technologies, driven by experts in the field, have grown the role of GRM in this sector. With the commercial transfer of vehicles to electric drive chains, the importance of battery optimisation, safety, cost and battery life play important factors in this process. The CAE expertise of GRM and the optimisation lead design approach to engineering lead to innovative results.

In the video below, JLR Systems Integration Manager, Markus Hose, delivers the key note at GRM's biennial conference - OED2018. He explained the power of optimised engineering design when delivered at a systemic level while working on JLRs Formula E car.

|

Contact us for examples of success and to discuss your particular requirements.

GRM Electrification Services

Click to load presentation in pdf viewer